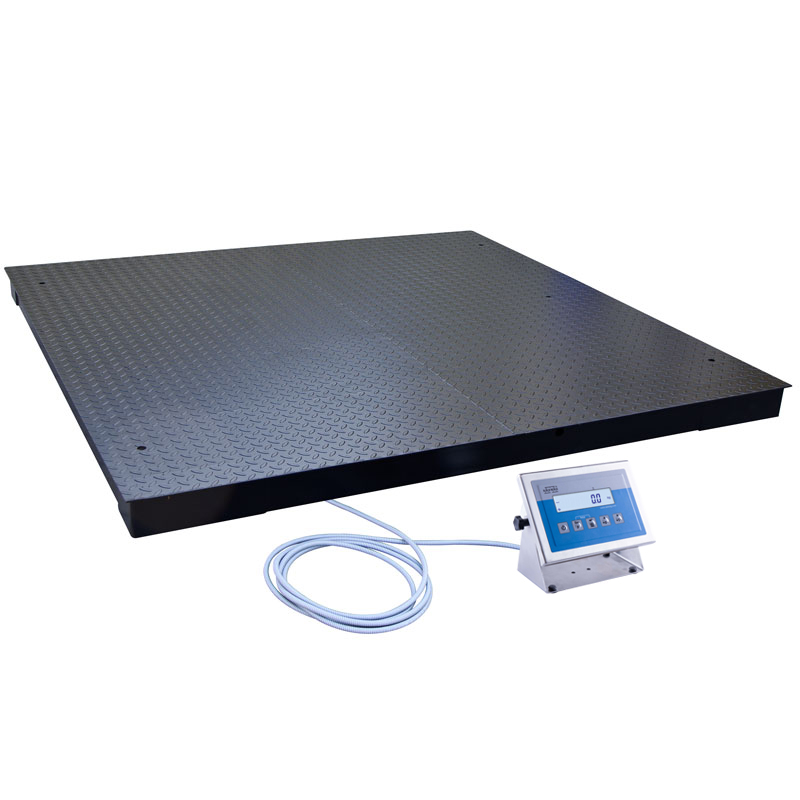

Description

A multi load cell system is designed to accurately measure weight across multiple points, ensuring precision in various applications. These systems are often used in industrial settings, such as batching processes and tank weighing, to enhance efficiency and reliability. By distributing the load across several sensors, they minimize the risk of overload and improve overall measurement accuracy.

Features

- Rugged construction permits use in all industries

- Gross capacity of load cell is 150% of rated capacity is provided to consider Impact load also

- 100% Tare facility eliminates error in weighing even if each container is of different weight

- Stainless steel cover(optlonal)

- Platform height can increase by placing a stand below plate form as per application

- Optional battery operated with in built battery charger

- Standard dimension of load cell for easy mounting

- A unique suspension design of load cell allows the platform to swing in the direction of the movement of load

- Absorbs lateral and transverse breaking force, which improves the life of the load cell

- Easy to install and hence reduced time of maintenance

- Auto Zero Tracking

- Inbuilt spike guard to protect machine from voltage fluctuations

- “Help” indication on display to indicate over loading. It enhances life of machine Approved from weights & measure department

Area of uses

- Heavy Load Industry

- Parcels

- Freight

- Engineering

- Wire Rod Industry

- Steel Industry

Options Available

- RS 232 COMPUTER INTERFACE WITH COMPUTER SOFTWARE TO PICK UP DATA FROM TEXT FILE

- THERMAL PRINTER OUTPUT WITH DATE, TIME & WEIGHT

- DATA LOGGER WITH 500 NOS.RECORDS OF WEIGHT, DATE, & TIME WITH DATA TRANSFER FACILITY IN MICROSOFT EXCEL SHEET

- WIRELESS DISPLAY TO MONITOR WEIGHING

- EXTRA DISPLAY WITH WIRE FOR MONITORING WEIGHT FROM CABIN

- SET POINT CONTROLS WITH RELAY OUTPUT

- RS 485 MODBUS INTERFACE FOR CONTROL FORM PLC PANEL

- 4-20 MA CURRENT OUTPUT FOR PLC CANTORS

Our Esteemed Client